Special Machine Construction

Development and engineering of machines and special machine construction

Via Engineering Deurne BV translates your wishes and ideas into a functional and cost-saving machine. Due to our extensive experience, we have a great deal of knowledge and expertise of special machines and turnkey projects.

In addition, Via Engineering Deurne BV has the right machines for manufacturing the parts and has specialized technicians for the assembly and test phase of the end product. We master every intermediate step of the process: concept phase, 3D design, machining, assembly and ultimately testing your machine.

We work closely with the right partners for industrial automation, electrical control systems and panel building, for example. This makes us all-round in various sectors and projects.

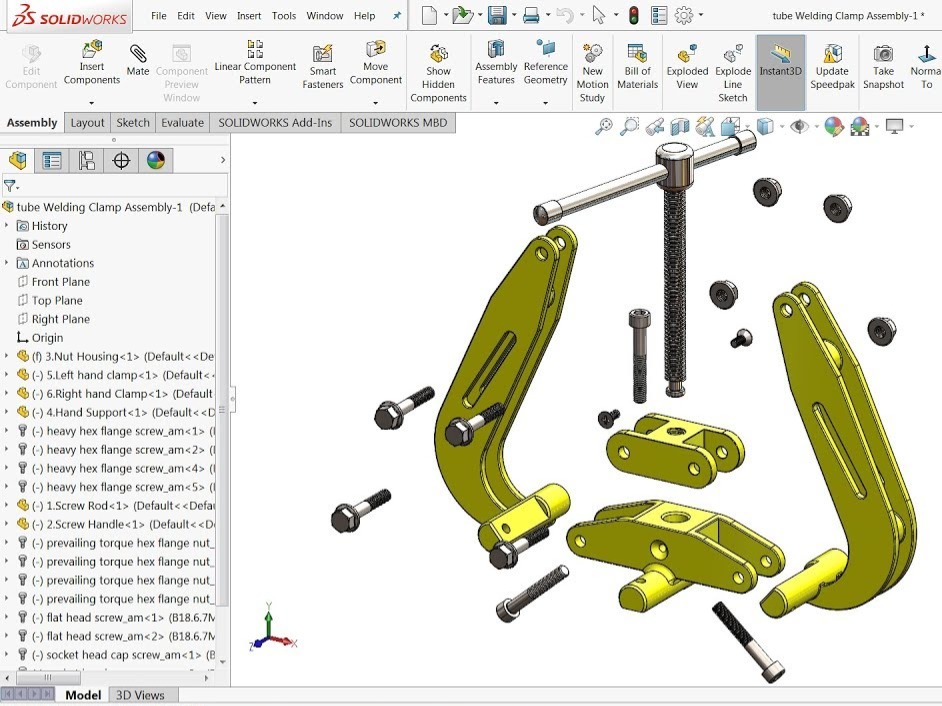

TOOLS AND MACHINE PARTS

Via Engineering also designs and manufactures tools and machine parts with various functions. The function of the product or part is always paramount. The manufacturability, in which the desired material and design are taken as a starting point, plays a major role in this. It is of course important that the price-quality ratio is in balance.

Via Engineering Deurne BV is able to tackle a customer's problem or issue and translate it into a technical challenge.

PROJECT DRILLING TOOL

This drilling tool is intended for double-sided drilling of different sizes of 3D printed plastic products. This special machine construction works completely pneumatically so that no PLC control was required. The pneumatic circuit is activated when the products are inlaid and the cover is closed. The cylinder clamps the products and it will drill the holes on the first product, then the slide will move to the other position and when this position is reached it will drill the holes on the second product. After this the carriage returns to its 'home' position and the cover can be opened.

A fast and efficient process to easily drill a large series of products. CE safe with a sleek and compact design.

"Via Engineering Deurne BV translates your wishes and ideas into a functional and cost-saving machine"

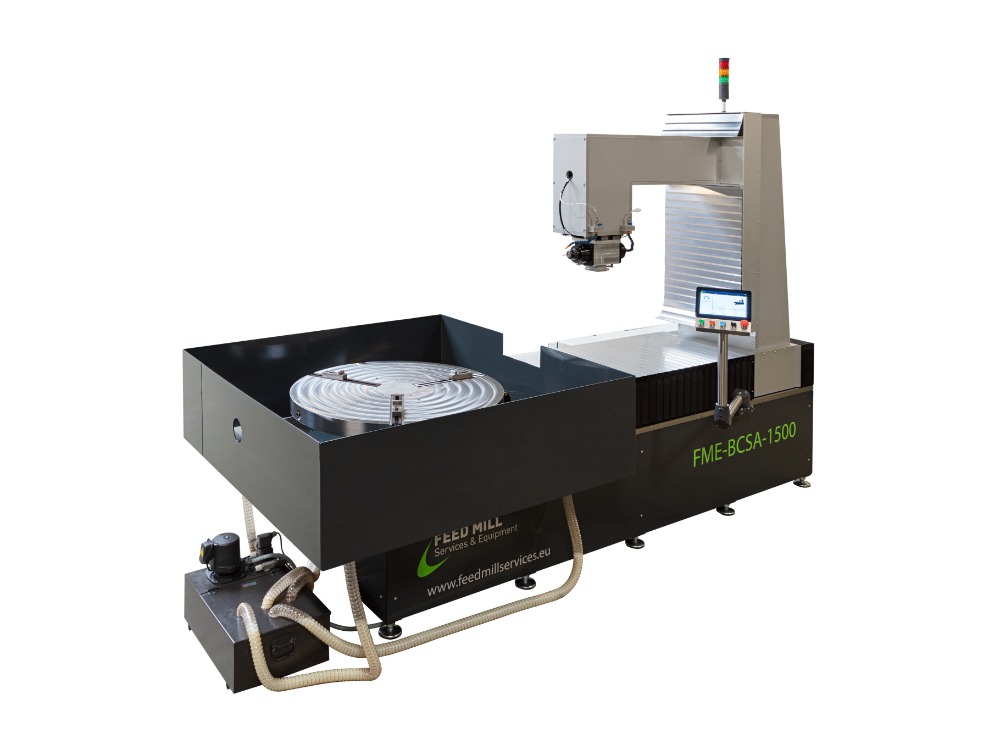

PROJECT COUNTERSINK MACHINE

This horizontal countersink machine was designed and developed to the wishes of a customer who processes large steel rings. The countersink machine can drill, ream and countersink holes on the inside and outside. It is a fast and efficient process to easily drill/countersink many holes. The drill head can be equipped with a multi-spindle drill head, which makes the process even faster. The C-axis (rotary table) ensures an accurate position of the workpiece and the Y-axis and Z-axis ensure an accurate drilling position.

This machine is equipped with a user-friendly control system and a complete coolant system. The countersink machine is placed inside a fence with safety light screen to comply with all safety regulations. Completely delivered turn-key by Via Engineering BV incl. user manual.

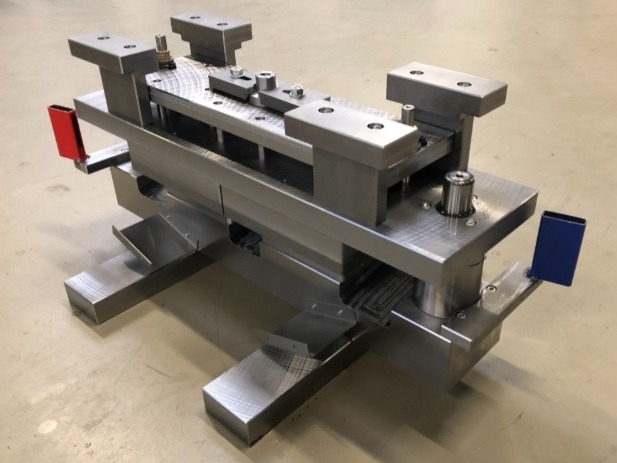

CUTTING STAMP

Via Engineering Deurne BV has a lot of experience in the design and development of cutting stamps for cast products. The function of this cutting stamp is to stamp the outer contour and holes of a product. The product is inlaid by means of a robot. The air pockets and castings are first removed by push pins on the top punch, after which the cutting plate recuts the contour. The product is pushed out of the top punch by an ejector plate.

PROJECT PICK & PLACE SYSTEM

This Pick & Place unit is custom designed and developed in consultation with our customer. Sawn round discs roll from a sawing machine onto the buffer system. These discs are picked up by vacuum. The product can then be rotated 90 degrees by a tilting mechanism. The product can be placed in the correct position on a trolley or pallet using the x, y and z axes.

Interested in our solutions?

Contact UsT +31 (0)493 312788 • E info@viaengineering.nl • I www.viaengineering.nl

Contact

Contact Menu

Menu